pcb

Soldering surfaces for printed circuit boards, Part 5: Organic Solderability Preservative (OSP)

Read more »

Katharina Luchner

16/02/2024

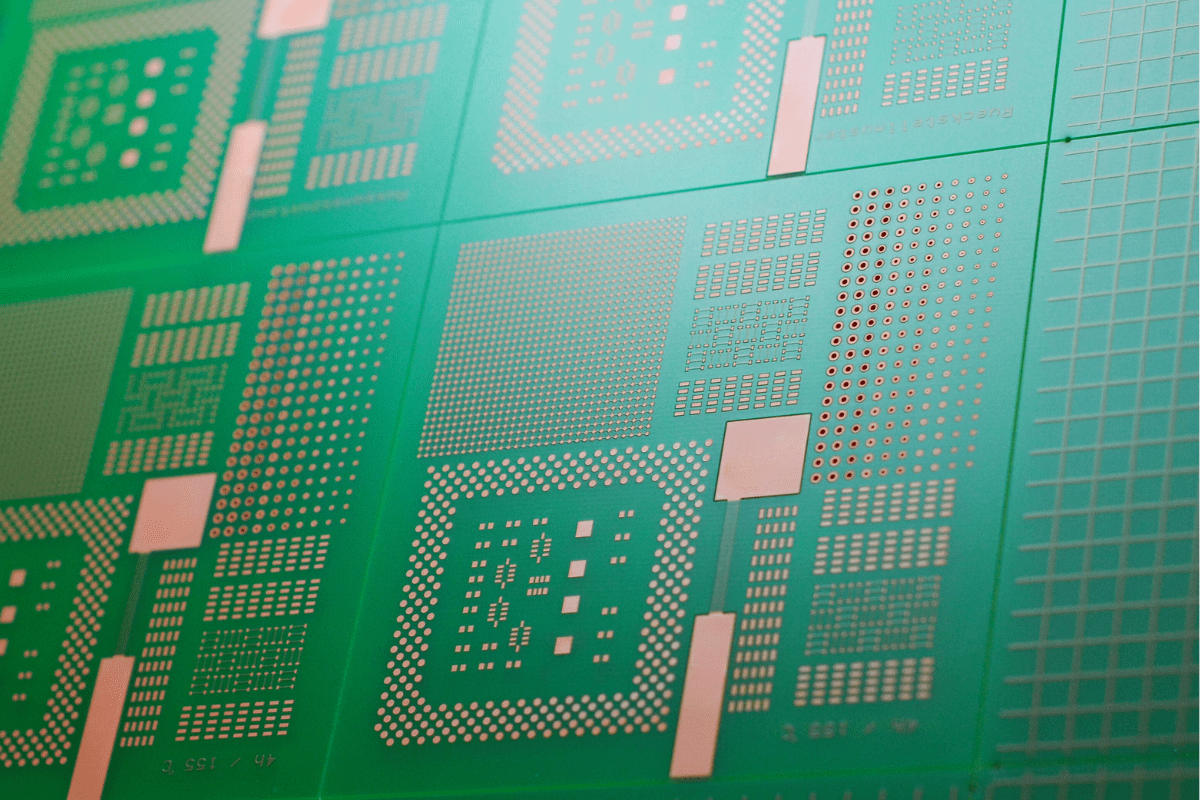

pcb

The cost-optimized printed circuit board. Savings potential for material & layer structure

Read more »

Christin Post

06/02/2024

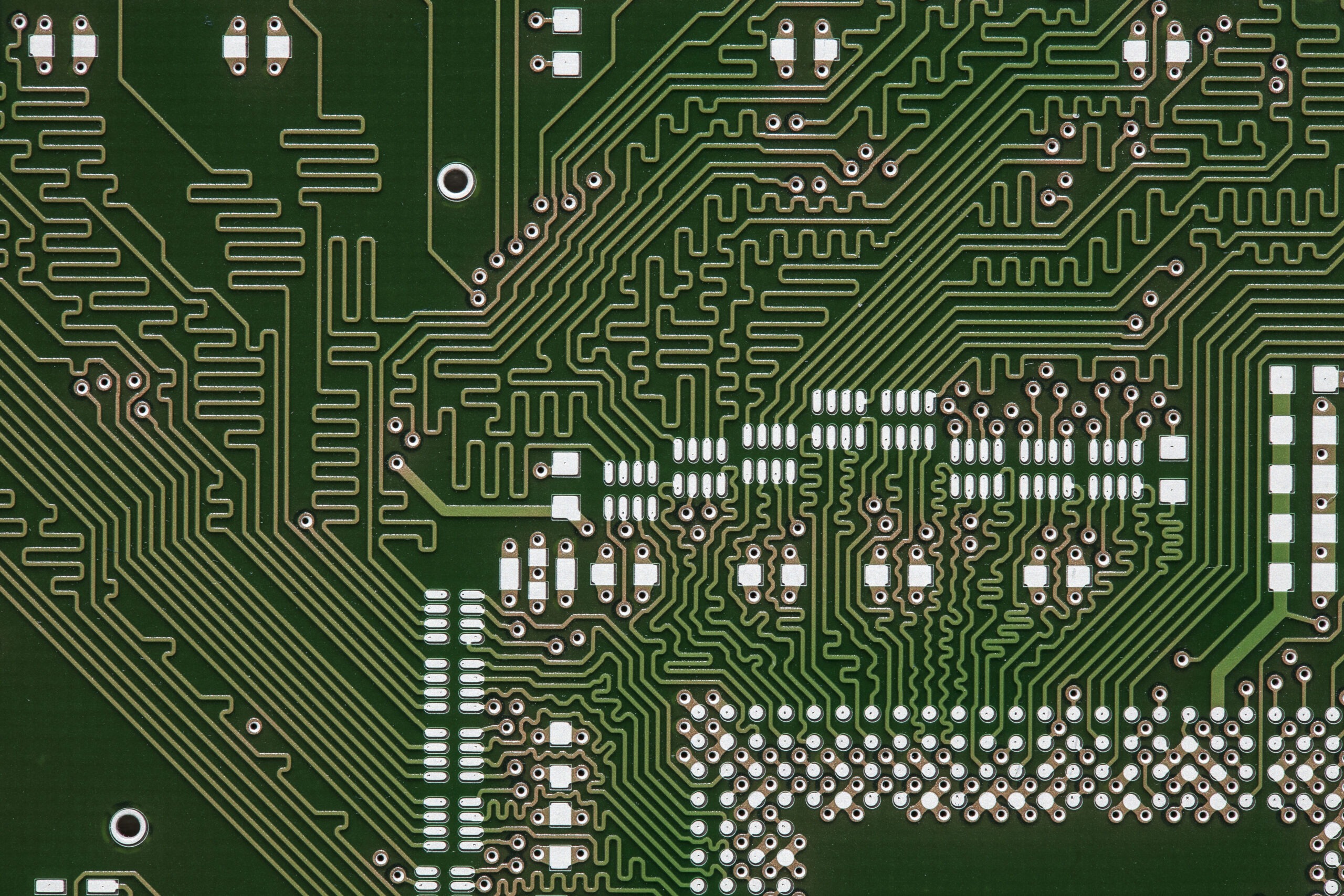

pcb

Pioneering technologies through precise impedance control: the role of the printed circuit board

Read more »

Laura Kaulfuß

03/01/2024

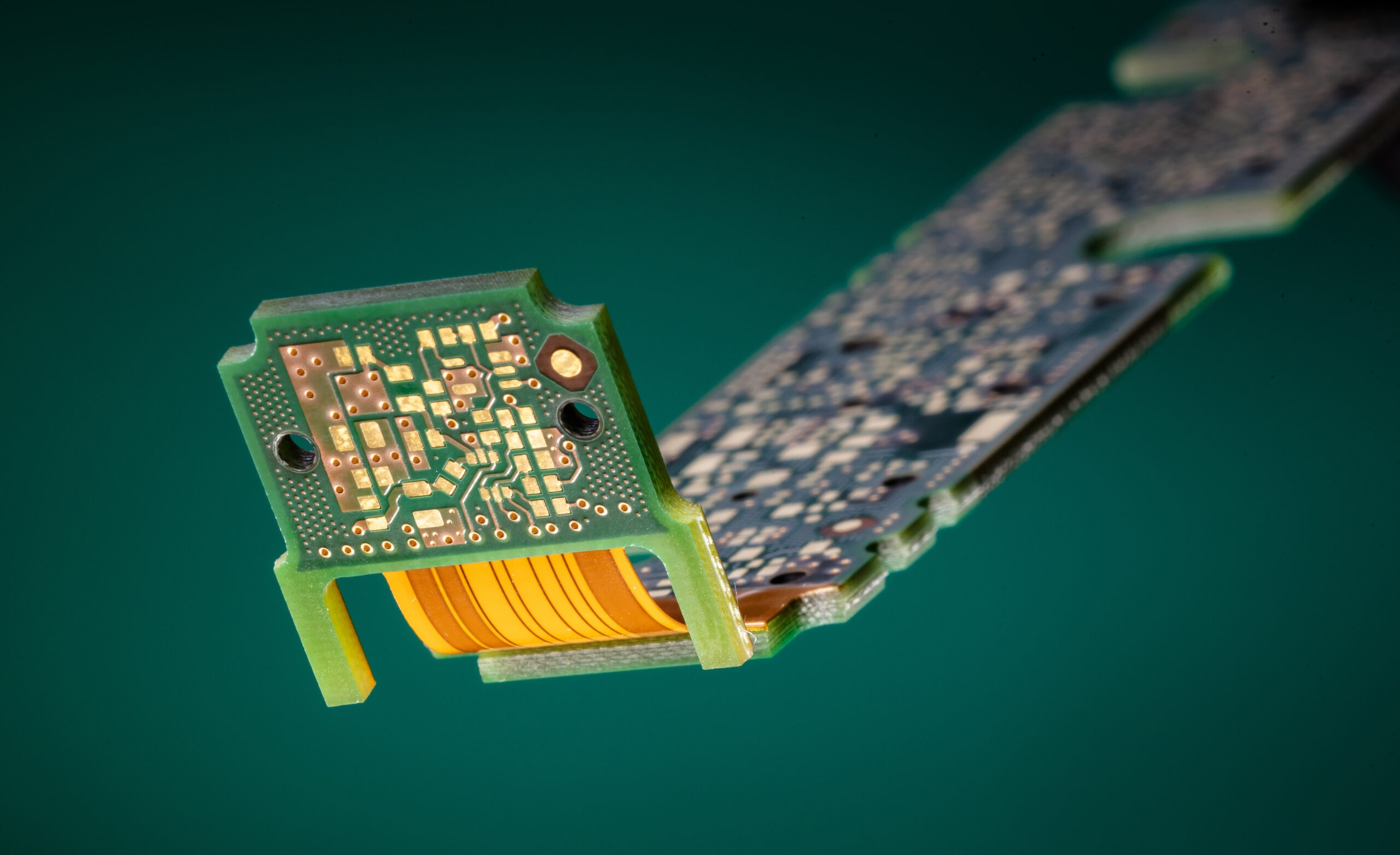

pcb

3D printed circuit boards in the area of conflict between functionality and cost optimization

Read more »

Laura Kaulfuß

01/12/2023

smarter

#smartertogether for over 30 years: GE HealthCare and KSG Group in harmony with progress and quality

Read more »

Christin Post

30/06/2023

together

Focus on digitalization and energy efficiency: An interview with Margret Gleiniger, CEO, and Swen Klöden, CTO, KSG Group

Read more »

Laura Kaulfuß

24/01/2023