In a time of constant change and advancing technologies, the urge to successfully bring groundbreaking innovations to market is not just an entrepreneurial endeavor, but rather the linchpin for sustainable success. Within this dynamic environment, defined impedance control on printed circuit boards occupies a decisive position that can make the difference between the success or failure of your application.

Printed circuit boards are the nerve tracts of the electronic world on which electrical signals pulsate. They are not only the connection paths between electronic components, but also the guardians of valuable signals, especially in the high-frequency ranges. The impedance, i.e. the resistance that an electrical signal experiences on a circuit board, plays a major role here.

The correct choice of material, the correct structure of the circuit board and a precise design are the three keys to taking control of this impedance.

Key no. 1: The choice of material

At low frequencies, the popular standard materials such as the good old FR-4 (glass fiber reinforced epoxy resin) are often sufficient. Overall, cost-effective solutions with acceptable impedance control can be achieved.

But beware! At frequencies in the higher GHz range, the choice of materials requires a more exclusive approach. Why? High-frequency signals can be attenuated due to losses in the PCB materials. To minimize this attenuation, we recommend choosing materials with a low loss factor, such as Rogers RO4835 or Panasonic Megtron 6. The price may be a little higher, but the reward is the best possible control over impedance.

Key no. 2: Sophisticated architecture of high-frequency circuit boards

Once you have chosen the right material, a sophisticated architecture is required to achieve the desired impedance, especially for high-frequency PCBs. Stacked structures, various materials and different layer thicknesses are usually used in this application. This requires extensive specialist knowledge, particularly in the design of the signal conductors, the reference conductors and the dielectric layer. The reference conductors are used to limit the electric field of the signal conductors, while the dielectric layer should have a low loss tangent in order to maintain the integrity of the signals.

Key no. 3: Keep an eye on the design!

- Distance and width of the signal conductor: Precision rules here. Adhere to the specified values according to our pre-calculation and our design guidelines.

- Transitions: Carefully designed connections and joints minimize reflections and impedance differences.

The KSG impedance turbo for your success

- Precise manufacturing and impedance measurement:

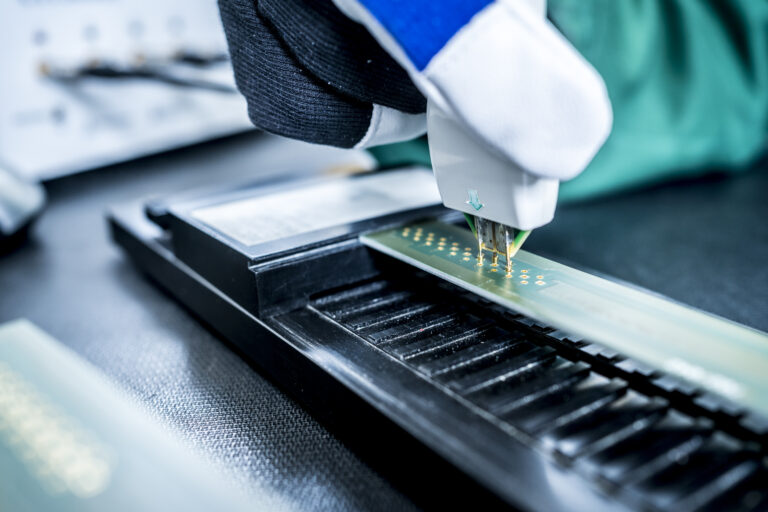

Impedance is measured at KSG during the manufacturing process. In this way, we ensure and check that it meets the requirements. - Better signal integrity: With precise signal transmission, your electronic devices will be reliable, free from signal interference and distortion.

- Higher performance: PCBs with defined impedance control enable the transmission of signals with higher data rates and lower losses – ideal for high-frequency applications!

- Product compactness: Shrink your application for more compact designs and lighter and more manageable electronic devices.

- Energy efficiency: Reduce signal loss and reflections for improved energy efficiency, especially in battery-powered devices.

- Cost savings: High-quality materials and special manufacturing processes lead to lower malfunctions and repair costs.

- Shorter development times: Standardized PCBs from KSG with defined impedance control shorten development times and accelerate the market launch of products.

- Competitive advantage: Reliable and high-performance products from KSG give you a competitive edge and strengthen your brand presence

All in all, PCBs with impedance control are the key to an exciting journey through the world of electronics. They improve the performance, reliability and efficiency of electronic devices, especially in industries where precision and signal integrity are paramount. We are happy to accompany you on this path – because our expertise and experience in the development of high-precision PCBs guarantee the highest quality so that your solution will be outstanding and sustainably successful.

The Design Compass shows the way

If you want to delve deeper into this electronic adventure, we recommend chapter 13 Impedance from our Digital Design Compass. This will guide you safely through the world of impedance.

Do you have further questions or comments about impedance control? Then write a comment. We look forward to the exchange!