Unfavorable environmental conditions such as temperature fluctuations or high humidity not only affect the surface of printed circuit boards. Conductive paths can also form inside the PCB between conductor structures with a potential difference, leading to a short circuit and causing a failure. In addition to the surface resistance, it is therefore also necessary to evaluate the volume resistance of the printed circuit board with regard to its long-term durability. The CAF test is used here as a suitable method.

What does CAF mean?

CAF stands for Conductive Anodic Filament and describes the physicochemical effect of ion migration – mostly copper compounds – along glass fibers within the printed circuit board. As a result of migration, conductive paths are created, which lead to a reduction in insulation resistance between live conductive paths. In extreme cases, this causes a short circuit or failure of the module.

What characterizes the failure process inside printed circuit boards?

Compared to superficial change processes, which can be determined by means of SIR testing, failure processes inside the PCB usually proceed more slowly. Furthermore, they are much more influenced by material selection, layout and processing conditions than by faulty handling or insufficient cleaning. The CAF test is becoming increasingly important, especially with ever smaller conductor spacing and overall part sizes in the course of miniaturization.

How does the CAF test work?

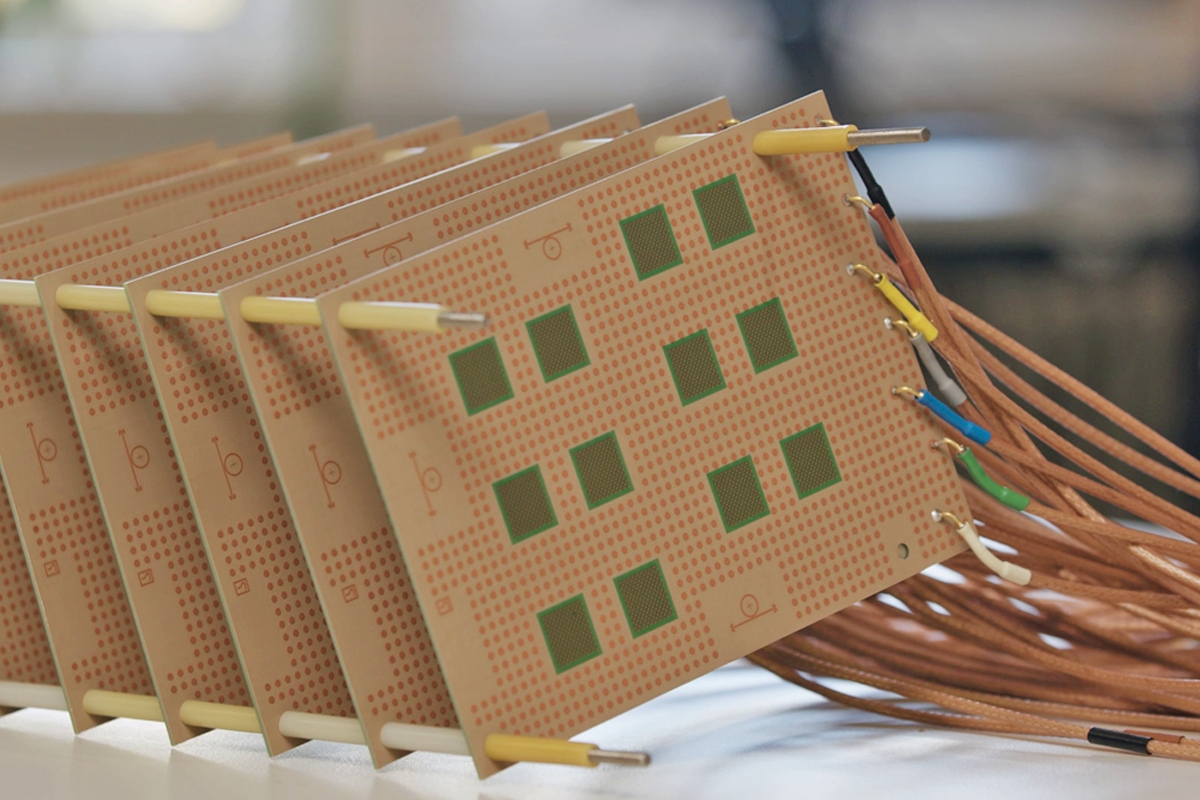

The test specimens with specific test structures are connected in the climatic cabinet with cables that are led to the outside to the resistance measuring system. The system measures the absolute resistance and leakage current in regular repetition, for example between rows of holes with opposite polarity or between holes and internal conductor runs.

Typical test conditions:

- Pre-aging: 3x reflow simulation lead-free soldering

- Temperature: 85° C

- Relative humidity 85

- Bias voltage: 100 – 1,000 V

- Test duration: 1,000 to 3,000 h

Either the resistance lower limit (10 MOhm), the maximum resistance drop with respect to the initial resistance (3 tens of percent) or also the leakage current upper limit are defined as failure criteria. The failure times are evaluated with the Weibull statistics and the desired service life parameters for this type of failure are provided.

How can failure processes inside the printed circuit board be avoided?

It is necessary to achieve high resistance to degradation of internal insulation properties. The following factors play a role:

- The selection of CAF-resistant base materials

- The use of ply lay-ups optimized in terms of z-axis expansion to avoid delamination during processing

- A layout check for minimum spacing

- The reduction of layout misalignment, which leads to the shortening of insulation distances

- The avoidance of process residues in the form of particles that shorten distances

- A clean handling

- A high cleaning quality in all intermediate processes

Where can I find more info about the CAF test?

Detailed information on the CAF test procedure as well as valuable expert tips directly from the KSG Group quality laboratory are available as part of the XPERTS online seminar “From Gigaohm to Short Circuit: Printed Circuit Boards in the CAF Climate Test” by Dr. Swantje Frühauf and Holger Bönitz. Click here to register.