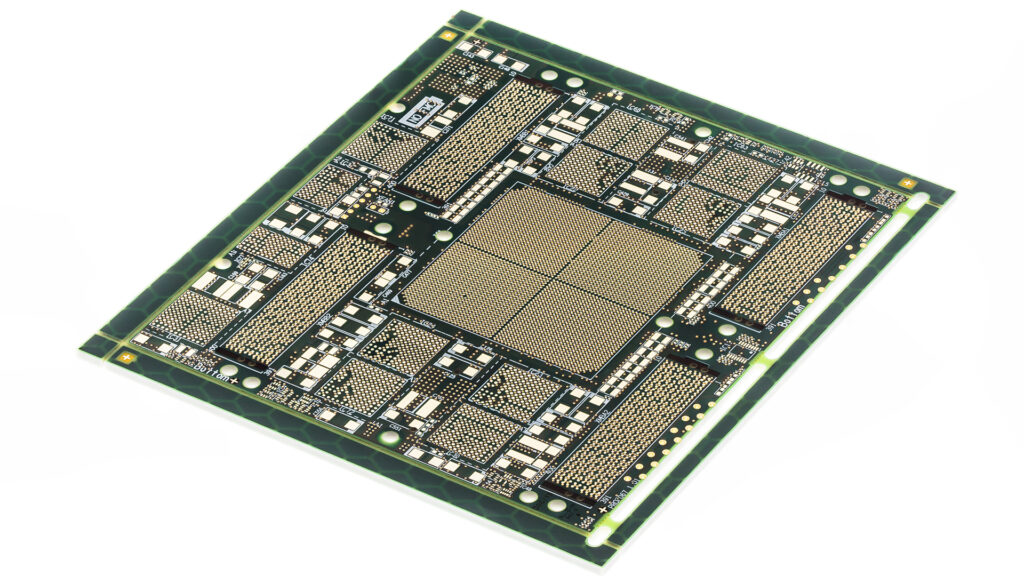

Qualification incl. UL listing Panasonic Megtron 6 successfully completed

KSG has received UL listing for the production of unpopulated printed circuit boards with the high-frequency material Megtron 6 after successfully passing UL testing of the sample sets. From now on we are authorized to apply the identifier “M6” for multilayer boards with Megtron 6 material (and analogously “S6” for double-sided boards). As one of […]

Qualification incl. UL listing Panasonic Megtron 6 successfully completed Mehr erfahren »