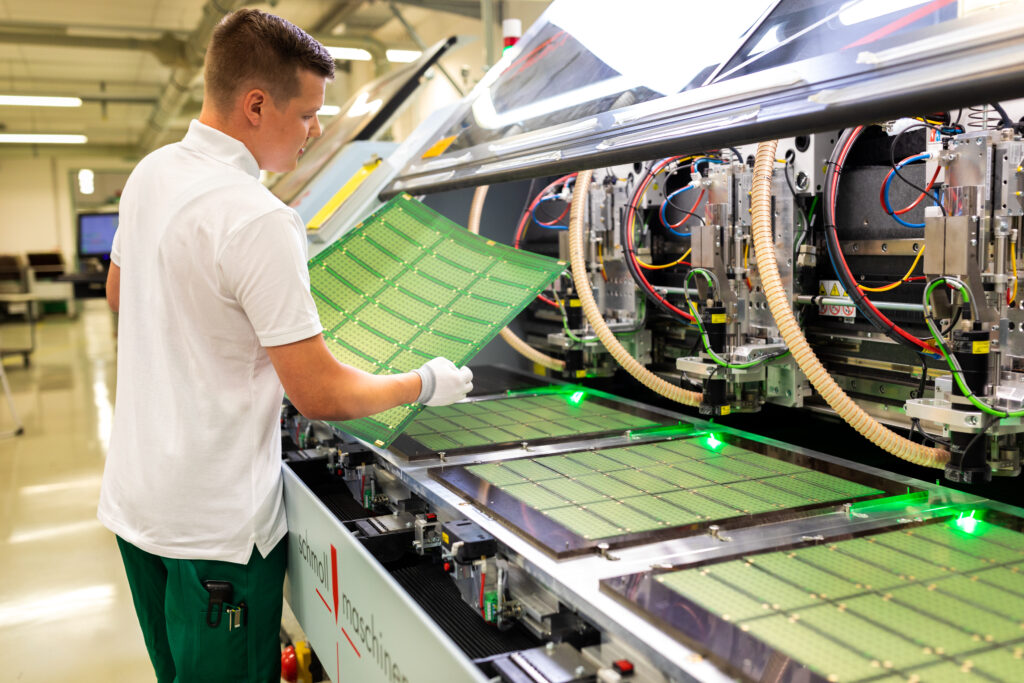

The stress test showed how agile and mobile our company is

The printed circuit board manufacturer KSG has mastered the past 18 months with entrepreneurial skill and customer service. The business situation is pleasing and the team has grown to meet the challenges. “We learned three things in the Corona crisis,” says CEO Margret Gleiniger. “Firstly, that we can change ad hoc and that changes are […]

The stress test showed how agile and mobile our company is Mehr erfahren »